Find all of the leading manufacturers of asynchronous motors on DirectIndustry.

Eureka Magazine invites you to come visit the DirectIndustry online industrial exhibition where you can find industrial products from leading manufacturers. Find all types of power transmission and automation products such as, asynchronous motors, motion controllers and gear reducers for your next design or project.

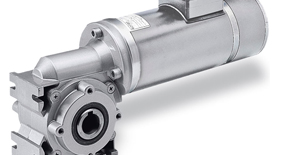

Gear-Motor.

For applications that require high torque and low turning speeds such as conveyors or lifting tables, gear-motors are a reliable and effective power transmission solution. The gear-motor combines a motor and reduction gear-box into one single unit. Manufacturers usually design gear-motors with specific gear ratios depending on the customers specific requirements. When selecting a gear-motor, be sure to specify the rotational speed (RPM), the required torque (N.m),(In.-Lbs.) and the power rating (kW),(V).

Servo-Motor.

A servo-motor provides precision control of speed, torque and position using a closed loop feedback control system. They can also maintain a desired torque at a fixed position for operations such as in robotic grippers or vertical lifts. The motor can either be AC, brushed DC or brushless DC depending on the complexity of the design. In order to provide feedback, servo-motors integrate encoders into the controller system.

Multi-axis Motion Controller.

Multi-axis motion controllers allow programmers to control multiple actuators or motors at the same time. They are capable of controlling up to 250+ axes all at the same time. For each individual motor the controller commands their torque, speed and position. Multi-axis motion controllers communicate generally through a Fieldbus network such as Ethernet. They are commonly used for robotics, CNC machining centers, pick & place machines and packaging machines.